- 200% : Water source replenishment. Focus on watersheds near our plant

- 30% : Water usage reduction by 2030

Resources

What we are doing

- In order to make effective use of valuable resources in a sustainable manner, we will make continuous devise and improve ways to contribute to environmental protection.

Key issues of the Sustainability Framework and SDG-related Initiatives

Resources

Packaging/PET

Water

Greenhouse gas emissions

Renewable energy

CSV Goals (Creating Shared Value) *The base year is 2015 and the target year is 2025 unless otherwise noted.

- 50% : Scope 1 and 2 reduction in greenhouse gas emissions by 2030

- 30% : Scope 3 reduction in greenhouse gas emissions by 2030

- Net zero in greenhouse gas emissions by 2050

- Promotion of renewable energy

- Design

-

- 50% : Content of sustainable materials* by 2022

- 100% : Content of sustainable materials* by 2030

- 100% : Use sustainable materials in PET bottles of all products (based on unit sales)

- 35% : Further lightweight PET packaging (compared to 2004) by 2030

- Collect

-

- 100% : Collection percentage compared to sales volume by 2030

- Partner

-

- Extensive partnerships across industry and environmental organizations by 2030

*Sustainable materials:Total of recycle PET material and bio-based PET plastic.

- Initiatives for Packaging/PET

- Initiatives for Water

- Initiatives for Greenhouse gas emissions

- Utilization of renewable energy

Toward Achieving a World Without Waste

2030 Packaging Vision

In 2018, The Coca-Cola Company (TCCC) has declared its vision to work towards a "world without waste" by launching a global initiative under this name to dramatically reduce the environmental impact of packaging. In January that year, the Coca-Cola system in Japan announced its own commitments as "2030 Packaging Vision" in which it laid out a set of environmental targets that align with TCCC's global initiative. Furthermore, to accelerate the progress of this global initiative, the roadmap set in "2030 Packaging Vision" has been renewed in July 2019 with shorter timelines aimed at achieving the targets earlier than the original due dates.

Based on this global initiative, the Coca-Cola system in Japan is undertaking activities built on the three pillars of "Design, Collect, and Partner" to resolve the problem of waste originating from packaging.

Three core elements of the 2030 Packaging Vision

Through the promotion of its bottle-to-bottle initiative, the Coca-Cola system in Japan is working to realize the 2030 Packaging Vision, with a primary goal of transitioning all PET bottles to 100% sustainable materials by 2030.

We are promoting bottle-to-bottle

recycling by improving the design

and material of our bottles to make

them more sustainable

We plan to collect and recycle the

volume of packaging equivalent to that

of products sold

We are building and maintaining stronger collection

and recycling schemes through partnerships with the

national and local government, the beverage industry,

and our communities

Roadmap to 2030

Unique packaging targets for the Coca-Cola system in Japan include: the use of sustainable materials, such as recycled PET, in all PET bottles by 2025; recovering a volume of PET bottles equivalent to that of the products sold in Japan by 2030; and the building of stronger packaging collection and recycling schemes in collaboration with partners.

Design

- 100% by 2025

- By 2025, sustainable materials, recycled PET plastic through "Bottle to Bottle*" and bio-based PET plastic, will be used in all PET bottles of all products being sold in Japan.

*In bottle-to-bottle recycling, used PET bottles are collected and processed for recycling before being remade into PET bottles for use as packaging for beverages. - 100% by 2030

- By 2030, the proportion of sustainable materials will be made 100% so as to aim for complete implementation of packaging not using fossil fuels.

- 35% by 2030

- By 2030, the amount of PET plastic used in each product will be reduced by 35% (compared to 2004).

Collect

- 100% by 2030

- Under our Collect initiative, our aim by 2030 is to be able to recover a volume of PET bottles equivalent to that of the products we sell in Japan.

Partner

- By 2030

- The building and maintaining of even more steady packaging collection and recycling schemes will be undertaken in cooperation with the Government of Japan, local governments, beverage industry, local communities so as to contribute toward further improving the already very high level of PET bottle and can collection and recycling rates in Japan.

Initiatives to achieve "2030 Packaging Vision"

- Design

- Collect

- Partner

Bottle-to-bottle

Bottle-to-bottle recycling As a part of achieving the aims of The Coca-Cola Company's "World Without Waste" global initiative, we are taking part in the bottle-to-bottle recycling project to convert used PET bottles into product ready PET bottles. Bottle-to-bottle recycling makes it possible to manufacture PET bottles with a lower environmental impact.

Sustainable materials*¹ used in PET bottles in the domestic soft drinks business

●Initiative for Bottle–to-Bottle

We have introduced 100% recycled PET bottles in in 4 brands and 44 products*² including flagship products such as Coca-Cola.These bottles are a product of our "Bottle-to-Bottle" initiative, in which we collect used PET bottles and make them into new ones to make full use of our resources.

In addition to “Bottle-to-Bottle” initiative, The Coca-Cola system in Japan utilize sustainable materials in approx. 90% of our PET bottle products in Japan(number of bottle sold), etc. through we expects*³ to reduce petroleum-based new plastics by around 29,000 tons and greenhouse gas emissions by around 26,000 tons annually overall through various initiatives.

*¹ Sustainable materials refer to the total bottle-to-bottle recycled PET materials and plant-derived PET materials

*² The Coca-Cola system in Japan performance in Japan as of December 2022.

*³ Total target products and 2022 sales forecasts based on 2021 shipment results represent preliminary calculations by Coca-Cola (Japan) Company.

-

1本でCO2

約60%※

削減へReduces CO2 emissions by approximately 60% per bottle**When switching from regular PET bottles to bottles with 100% recycled PET materials

●I LOHAS Tennensui 100% recycled PET bottles

"Bottle to Bottle" where we recycle PET bottles as resources

The Coca-Cola system in Japan is promoting the bottle-to-bottle recycling and has set a goal in the 2030 Packaging Vision to increase the rate of PET bottles made from recycled PET resin or bio-based PET plastic to 100% by 2030. In Japan, we use sustainable materials* in more than 90% of the PET bottle products (number of bottles sold) sold in Japan. By launching I LOHAS Tennensui 100% recycled PET bottles, we have taken a big step toward our goal of "World Without Waste."

The bottles of I LOHAS Tennensui in the past contained 30% of recycled PET material.

However, in March 2020, we successfully launched I LOHAS Tennensui in "100% recycled bottles" on the largest scale in Japan*² by working with our partner companies and implementing technologies with challenging requirements that improved the transparency of recycled PET bottles by 30%.

*¹ Sustainable materials refer to the total bottle-to-bottle recycled PET materials and plant-derived PET materials

*² Comparison with the conventional 555ml of I LOHAS Tennensui

Initiatives for Labelless bottles

●I LOHAS Tennensui

A first for the Coca-Cola System - Environment friendly labelless bottles that are easy to sort

I LOHAS Tennensui Labelless launched in April 2020 eliminates the need to remove labels and makes it easier to sort waste. It is an environment friendly product which uses 100% recycled PET bottles for the package. This product is sold only in cases (online sales, etc.) The sale of the labelless bottle was made possible by printing the legally-required information such as raw materials, etc. (normally printed on the drink label) on the exterior of the cardboard.

Furthermore, a "complete Labelless product" that omits the identification mark on the label seal was realized, in line with revisions to the "Act on the Promotion of Effective Utilization of Resources for Labeling of PET Bottles" in April 2020. The amendment aims to promote the reduction of waste (reuse) and to eliminate consumers' need to separate label seals. This makes it easier to recover used PET bottles in a state suitable for recycling.

Reduced volume of plastics

●Packaging lightweighting

Since 1970, the Coca-Cola System has been committed to making effective use of limited resources and reducing the weight of packages in order to reduce the amount of plastics. Our representative development includes "Eco-ru bottle shiboru" and "Pekoraku bottles" that are easy to crush and easy to pour. We are also aiming to reduce the usage amount of PET resin per bottle by 35% between 2004 and 2030.

From spring 2021, the packaging weight of 700ml Coca-Cola PET bottles reduced from 42g to 27g. In addition, in April 2022, Coca-Cola and Coca-Cola Zero Sugar 100% recycled 350ml PET bottles, 2g lighter than the conventional labelless bottles of the same size (bottle weight 21g).

And others, we initiative that reduced the weight of Georgia Japan Craftman 500ml PET bottles from 19.5g to 17g, and Costa Coffee 265ml PET from 29.5g to 18.5g.

* Packaging for water was 500ml up till 2010

* The weight of the can is calculated by the weight of the can body and the can lid

●Other Product Lineups

Starting with I LOHAS products released in April 2020, currently manufacture 21 labelless products across 10 brands, including Ayataka, Sokenbicha, THE TANSAN STRONG From Canada Dry, Aquarius, Coca-Cola, and Georgia. We plan to steadily expand our range of labelless products in the future.

Initiatives for environmental design friendly

●Introduction of sustainable packaging

ecoru shiboru bottle

We have introduced packaging like the ecoru shiboru bottle, which is easy to twist and flatten after drinking, to reduce both environmental impact and energy use.

●Environmentally Friendly Materials

We are driving the use of consumer materials that are kind to the environment.

We promote the use of paper cups, straws, and newly introduced paper lids which had previously been plastic. We will push the further use of paper materials to reduce plastic consumption.

Examples of environmentally friendly materials used by our company

Collaborative initiatives with stakeholders

Horizontal recycling scheme developed from collection to recycling of used aluminum cans

In December 2022, Coca-Cola Bottlers Japan Inc. , in collaboration with Artemira Co., Ltd. and MA Aluminum Corporation, the company has kicked off the production of three products using 100% recycled aluminum materials including CAN to CAN as raw materials for the bottle can body, as part of the CAN to CAN horizontal recycling initiative of aluminum cans, in which used aluminum cans are collected from recycling boxes placed next to vending machines operated by CCBJI.

Our three products, Georgia Kaoru Black 400ml, Georgia Kaoru Bito 370ml, and Bonaqua (Nansui) 400ml, which use 100% recycled aluminum materials including CAN to CAN for the bottle can body, are scheduled for launch from January 2023.

Joint project to recycle PET raw material with Far Eastern New Century (Taiwan)

CCBJI started a joint project with Far Eastern New Century Corporation, one of the world's largest manufacturers of PET resin and polyester fibers, based in Taiwan, to commercialize PET bottles using recycled PET raw materials through chemical recycling. This project aims to carry out pilot sales of PET-bottled product using recycled PET raw materials in some of our sales areas by the end of the year and expand opportunities to leverage this PET raw material at commercial scale in several years.

Developed of Chemically Recycled Shrink Labels

We have jointly developed shrink labels with Fuji Seal and Toyobo that partly use PET resin recycled from reject labels in the manufacturing process. (*) This was achieved through a chemical recycling process developed by the Far Eastern New Century Corporation of Taiwan. Pilot sales of the PET bottle products using these labels are ongoing.

* Labels discarded in the process of shrink label production

Under our Collect initiative, our aim by 2030 is to be able to recover a volume of PET bottles equivalent to that of the products we sell in Japan.

Collaborative initiatives with stakeholders

Cooperative ventures with local governments

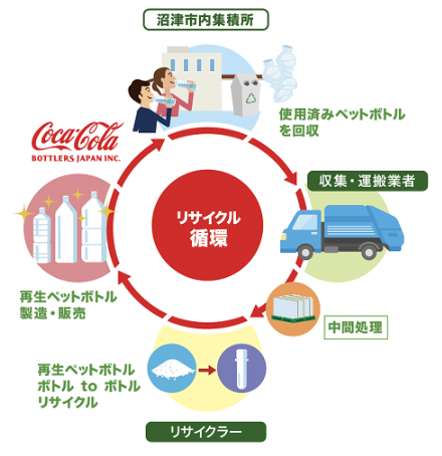

CCBJI is working with local governments to promote horizontal recycling of PET bottles via the bottle-to-bottle venture.

In alignment with the Coca-Cola System’s 2030 Packaging Vision, we aim to foster the circular utilization of PET bottles in Japan by establishing a reliable collection and recycling scheme that brings together citizens, business, and government.

● Cooperative bottle-to-bottle venture with Tokai City, Aichi Prefecture

In July 2023, we signed an agreement with Tokai City, Aichi Prefecture, for the purpose of promoting bottle-to-bottle horizontal recycling of PET bottles.

● Cooperative bottle-to-bottle venture with Nishinomiya City, Hyogo Prefecture

In March 2023, we signed an agreement with Nishinomiya City, Hyogo Prefecture, for the purpose of promoting bottle-to-Bottle horizontal recycling of PET bottles.

● Cooperative bottle-to-bottle venture with Numazu City, Shizuoka Prefecture

In February 2023, we signed a "Business Collaboration Agreement on PET Bottle Resource Recycling" with Numazu City, Shizuoka Prefecture, for the purpose of implementing "Bottle to Bottle" horizontal recycling of PET bottles.

Cooperative initiatives with business partners

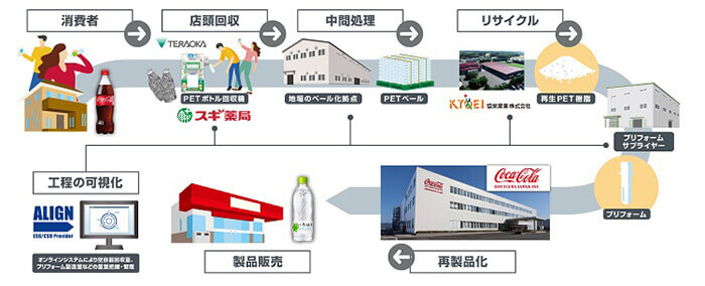

● Bottle-to-Bottle venture with Sugi Pharmacy

In April 2023, we launched a new bottle-to-bottle project that collects used PET bottles from designated Sugi Pharmacy stores in Aichi and Mie Prefectures, and breaks them down into raw materials for our new products.

We plan to gradually expand this collection area over time, aiming to further contribute to the recycling of PET bottles in Japan.

● Bottle-to-Bottle Program Collaboration with Mitsubishi Estate

In June 2022, we enacted a Bottle-to-Bottle Recycle Circulation in collaboration with Mitsubishi Estate to recycle PET bottles, collected from offices in the Marunouchi area of Tokyo.

The Bottle-to-Bottle program collects used PET bottles from nine buildings managed by Mitsubishi Estate. We also use our vending machines and recycle boxes to encourage tenants to separate used PET bottles for recycling.

●Realizing 100% recycling with Seven & i Holdings

Hajime Series, the products jointly developed with Seven & i Holdings Co., Ltd., have been on sale since June 2019. The products are sold in 100% recycled PET bottles made only from PET resin generated from the recycling of used PET bottles collected from Seven & i Group stores. By switching to 100% recycled PET bottles, we have achieved a reduction in CO2 emissions.

※This product is as of August 2023

Collaborative efforts with the stakeholders

●JSDA(The Japan Soft Drink Association's) "Declaration of 50% Bottle-to-Bottle by 2030"

We have endorsed JSDA declaration on the recycling of plastic in the beverage industry— announced in 2018—with the goal of achieving the 100% effective utilization of PET bottles by fiscal 2030, and we are collaborating with our industry peers in initiatives.

JSDA announced “Declaration of 50% Bottle-to-Bottle by 2030” in April 2021.

It represents the soft drink industry’s aim to increase the usage rate of the recycled resin which is made in the process of "Bottle-to-Bottle horizontal recycling" of used PET bottles into new PET bottles, to 50% or over by 2030 to contribute to the recycling society and reduce the environmental burden including CO2.

Based on the "2030 Packaging Vision" set forth by the Coca-Cola system in Japan, we will continue to promote "Bottle-to-Bottle" activities in cooperation with the soft drink industry.

Effort to prevent anything other than empty bottles

●Attaching consumer awareness stickers

To promote understanding of the role of the recycling box next to vending machines and reduce the rate of foreign material contamination, we have attached approximately 90,000 industry-unified educational stickers (CCBJI) promoted by Japan Automatic Merchandising Association of which we are a member, in the Tokyo metropolitan area, Chubu area, and Kinki region to encourage customers not to insert any items other than empty containers.

●Demonstration experiments on new design of recycle box

Part of the bottle-to-bottle Tokyo Project, which was established with the Tokyo Metropolitan Government in 2020, involves conducting trials to, for example, change consumer behavior with regard to sorting recyclables and to prevent anything other than empty bottles from being placed in recycling bins.

Newly designed recycling bin

(hole is facing downward)

Under our Partner initiative, we are working to build and maintain more robust recovery and recycling schemes through collaboration with the national and local governments, the beverage industry, and our communities.

Collaborative initiatives with stakeholders

Cleanup activity

We work with our partners to achieve the 2030 Packaging Vision through cleanup activities in each region.

We also make efforts to clean rivers and oceans to improve the soundness of watersheds around each plant.

Cleanup activities with local residents

CCBJI and the Coca-Cola system in Japan have been participating in International Coastal Cleanup (ICC) (*) since 2007 as part of our efforts to realize our global vision, “World without Waste”.

In 2023, a total of 100 people, including President Calin, Coca-Cola (Japan), Yoshimi Town Office, NPO Green Bird and FamilyMart, participated as one team to realize World Without Waste in Yoshimi-machi, near the watershed area of Saitama Plant.

*International Coastal Cleanup (ICC) is the world's largest coastal cleanup campaign, launched by the largest marine conservation organization in the U.S., established as an environmental education center for marine life. It is prominent in its approach to collect marine waste data around the world using the same method to solve the global waste issue.

Other activities

Umeda River Cleaning (Miyagi), collaborated with NPO Green Bird (Tokyo and others), Beach Cleanup in SUMA (Hyogo), Zero Waste Clean Walk Hiroshima (Hiroshima), Oyama General Cleanup (Tottori), MyonoTanigawa Cleanup Volunteer Activities (Ehime), Love Earth Cleanup (Fukuoka), Shirakawa Cleanup (Kumamoto)

Joint research with the Nippon Foundation on how trash ends up in rivers

In February 2020, the Nippon Foundation and Coca-Cola (Japan) reported on the "Joint survey on waste outflow mechanism from lands to rivers," aiming to promote the proper collection and recycling of plastic resources as well as the countermeasures against marine waste announced in May last year. It was found that the causes of the occurrence were oadly divided into two categories: "Dumping and throwing away of waste" and "leakage." As a future effort, Coca-Cola System will take top priority on measures to prevent leakage from the empty container collection boxes beside the vending machines, which have been confirmed to have "leakage" of empty beverage containers.

Recycling Materials & Packages

We strive to reduce environmental impact by collecting and recycling as much as possible of the waste generated throughout a product's life cycle. Through various initiatives such as reducing waste generated by production, using inventory controls to reduce product disposal, making containers easier to recycle, and using environment-friendly containers, we are contributing to the development of a sustainable society.

Recycling of plant waste

Recycling waste materials at our plants, we sort and recycle waste materials generated by production to continuously aim to achieve zero waste emissions. Coffee grounds and tea leaves constitute the bulk of our generated waste materials, and we have achieved 100% and 100% recycle rates for them, respectively, as fertilizer or animal feed.

For example, the used tea leaves that result from the production of Sokenbicha at the Zao Plant are combined with byproducts, such as leftover whey from the manufacturing of cheese at the Zao Dairy Center, and used as "eco-feed" * for Zao Sosei beef cattle. Working with the local government and members of academia, the Tokai Plant is also pursuing research into a way to efficiently reuse coffee grounds and tea leaves.

* Food scraps that become feedstuff for animals. The Japanese Ministry of Agriculture, Forestry and Fisheries is actively promoting eco-feed to increase the self-sufficiency rate for feedstuff.

waste from plants

Recycling vending machines

We recycle vending machines that are taken out of service for disposal. Such vending machines are collected at our company's facilities, dismantled and sorted according to waste material type, and the chlorofluorocarbon is appropriately disposed.

A global vision for its new water security strategy

Water is the first ingredient in most of our beverages. It is also central to the sustainability of our business and the health of our communities. In March 2021, the Coca-Cola system announced a global framework for its new water security strategy looking ahead to 2030. The new strategy focuses on conserving sustainable water resources through water replenishment in communities, advocacy for more stringent policy and responsible water use in our operations and the community. With eyes on the entire value chain, The Coca-Cola company aims for 100% replenishment at each of our production facilities and look to support communities around watersheds where floods and droughts are starting to occur due to global warming. We are shifting our focus toward making a greater impact on people and ecosystems. We will enhance replenishment activities using diverse methods to match the conditions of each area as we keep targeting at least 100% replenishment of water sources and watersheds for all plants.

Since we engage in business that relies on the indispensable resource of water, we promote water resource conservation with the goals of reducing water use by 30% by 2030, and maintaining a 200% water resource replenishment rate through 2025.

At our plants, we strictly manage the water used to manufacture products while continually reviewing and improving manufacturing processes and plant equipment in order not to waste any of this precious natural resource. The reduction target is set for the water use ratio (WUR) of product manufacturing per liter of product. We work to conserve water resources by cooperating with communities and experts in efforts to return to nature a volume of water equivalent to the amount of water used for manufacturing products, and to contribute to the ability of water resource areas to sustainably cultivate and store water.

The Coca-Cola system's water cycle

Within the Coca-Cola system, we regularly assess the vulnerability of water sources in line with the resource conservation guidelines established by Coca-Cola Japan and we develop conservation plans for the water we use at our plants.

These plans are the basis for our activities that focus on reducing the amount of water used in the manufacturing process, recycling what water is used in manufacturing, and replenishing* water resource areas.

The water we use is classified into two major categories: water used for manufacturing, and used in products. The water used for manufacturing-specifically for rinsing and cooling- is collected, processed, and then reused. After proper treatment, it is eventually discharged into rivers. For the water used in products, we work to return its equivalent to nature by contributing to better groundwater recharge capacity through activities that include planting trees, thinning forest undergrowth, flooding rice fields, and regenerating grasslands, as well as by cultivating abundant underground water reservoirs.

*Replenish(ment): Efforts to return water used in products to nature by enhancing the infiltration function of water source forests through forest conservation activities.

*As of December 2023

Plant initiatives and watershed activities

Plant initiatives to reduce water use 30%

At our plants, we are working to reduce the amount of water used and to reuse the water we do use by installing production lines equipped with the latest technology, and by improving the manufacturing processes and plant equipment by monitoring them on a daily basis.

Wateshed activities to maintain a 200% replenishment rate

With the target of returning to nature a volume of water equivalent to the amount used for manufacturing products at our plants, we have also entered into agreements with local communities and organizations. Alongside members of local communities, we are promoting activities to enhance water source replenishment, which is the ability for the watershed areas supplying groundwater to our local manufacturing facilities to sustainably cultivate and store water.

The water cultivated through these activities will generate groundwater reservoirs over the years to come, and that water will make its way through rivers to our plants where it can be used for product manufacturing.

Conclusion of an agreement for the conservation of water resources in the plant's water source area

| Production plants | Water resource areas | Agreements with organizations |

|---|---|---|

| Zao plant | Zao town, Miyagi | Zao town, Shiroishi Zao Forestry Association, Enda Industrial Forestry Association |

| Saitama / Iwatsuki plants | Katashina village, Gunma | Nippon Paper Industries Co., Ltd., Marunuma Kogen Resort |

| Ibaraki plant | Ishioka, Ibaraki | Ishioka city, Tsukubane Forestry Association |

| Tama plant | Higashikurume city, Tokyo | Tokyo Metropolitan Government, Community Partnership Support Center (NPO) |

| Hachioji city (Tokyo) | Hachioji city | |

| Tabayama village (Yamanashi Prefecture) | Tabayama village | |

| Ebina plant | Atsugi city, Kanagawa | Kanagawa Prefecture, Atsugi city, Atsugi Forestry Association, Central Kanagawa Prefectural Government Center, Sagami River Left Bank Land Improvement District (Kanagawa) |

| Hakushu plant | Hokuto city, Yamanashi | Yamanashi prefecture |

| Tokai plant | Ena city, Gifu | Nakanohocho Area Council, Sakaori Tanada Preservation Association, Gifu Prefecture, Ena city |

| Kyoto plant | Ujitawara town, Kyoto | Kyoto Model Forest Association (NGO), Ujitawara town, Kyoto Prefecture, Tachikawa Industrial Forestry Association, Ujitawara Forestry Association |

| Akashi plant | Tamba-Sasayama city, Hyogo | Hyogo Prefecture, Hyogo Prefectural Greening Promotion Association (NGO), Tamba-Sasayama city, Tamba-Sasayama City Property Ward, NPO Hyogo Tamba Forestry Association, Hyogo Forestry Cooperative Federation |

| Daisen plant | Hōki town, Tottori | Tottori Prefecture, Hōki town, Tottori Hino Forestry Association, the district of Kanaya |

| Hiroshima plant | Mihara city, Hiroshima | Hiroshima Prefecture, Mihara city, Bisan District Forestry Association |

| Komatsu plant | Saijyo city, Ehime | Ishizuchi Forest Association |

| Tosu / Kiyama plants | Tosu city, Saga | Kyushu Forest Management Bureau |

| Saga Prefecture, Tosu city, Saga Eastern Forestry Association | ||

| Kiyama town, Saga | Saga Prefecture, Kiyama town, Saga Eastern Forestry Association | |

| Kumamoto plant | Aso city, Kumamoto | Aso city, NPO Aso Green Stock, Water Cycle Farming Promotion Council |

| Ebino plant | Ebino city, Miyazaki | Miyazaki Prefecture, Nishimoro District Forestry Association, Fumoto Public Forest |

●Initiatives for Sustainable Water Resources at Tama Plant Watershed

On July 31, 2023, our company and Coca-Cola (Japan) Company, Limited. announced about the agreements reached in June with Tabayama Village (Yamanashi Prefecture) and Hachioji City (Tokyo). These agreements are centered around the shared goals of conserving water resources at Tama plant (located in Higashikurume City, Tokyo) watershed.

Tambayama Village is located in the northeastern part of Yamanashi Prefecture, where the Tamba River, the source of the Tama River, flows. In this village, where 97% of the total area is forested, forest maintenance will be carried out with the aim of conserving water resources.

Hachioji City has 16 first-class rivers that flow into the Tama River. In Kamikawa no Sato, which has been designated as a special green conservation area for the purpose of preserving a good Satoyama environment. In addition to forest conservation, we are also working on restoring wetlands such as fallow paddy fields.

With these agreements, we expect to achieve a 100% water resource replenishment rate across all 17 of our manufacturing plants.

<PR videos>

「Mizu to Mito Tama plant」 Full

「Mizu to Mito Tabayama village」 Short

「Mizu to Mito Tabayama village」 Full

「Protecting Japan’s water abundance Coca-Cola / Tabayama village」 Full

Biodiversity Conservation

The CCBJH Group’s environment policy defines one of our missions as making effective use of water and other natural resources. Such natural assets are indispensable to both our business activities and must be passed on to future generations in a sustainable manner.

As a company that uses water for its business, it is essential to protect ecosystems such as forests, grasslands, and water sources. Our CSV water source goals prioritize their efficient use, waste reduction, and replenishment. Based on these objectives, we have been making efforts to conserve and replenish water as well as sustain biodiversity in priority areas.

We enter into agreements with local forestry cooperatives in all water source areas of our 17 plants. We conduct activities to preserve the environmental benefits of forests to the fullest and protect biodiversity for years to come.

In 2022, we became a member of the TNFD Forum and began assessing the impact on biodiversity in watersheds. We are conducting environmental impact assessments in regions with significant biodiversity, following guidance from external experts. Our aim is to prevent and reduce risks, and we will monitor and disclose the outcomes of our efforts.

Initiatives in Minamisawa, Higashikurume to Protect the Tama Plant Watershed

In April 2022, we entered into an agreement with the Tokyo Metropolitan Government as part of the "Agreement on Tokyo Greenship Action". The aim is to engage in natural environment conservation activities in the "Minamisawa Green Conservation Area", which serves as the water source area for the Tama Plant.

In October 2022, we partnered with the Higashikurume Nature Foreai Volunteers to organize the "Learn from the Forest" project in Tokyo's Higashikurume region. During the project, we had the opportunity to observe various plant and insect species, including the Anemone nikoensis, Anemone flaccida, and Calopteryx atrata. These are considered red-listed, which means they are of significant importance for conservation in Tokyo.

The project helped us recognize the area's value in terms of biodiversity. The participants, including Tama Plant employees, worked together to maintain the promenade, contributing to the preservation of a diverse natural environment.

"Learn from the Forest" project in Tokyo

Conservation Measures in Sasayama Forest Park: Safeguarding Akashi Plant's Watershed

Since 2008, we have been involved in corporate forestation activities in partnership with Hyogo prefecture and others. As part of this initiative, we have named a section of the forest park "Watershed Forest Tambasasayama" and have been undertaking forest conservation activities in the water source area of Akashi Plant for several years.

In November 2022, we organized the "Learn from the Forest" project in Tambasasayama, where participants, including Akashi Plant employees, learned about the importance of preserving Satoyama areas and restoring species diversity. The project also highlighted the pressures of overfeeding from deer populations*1.

To protect the endangered golden orchid*2 that grow in the area, participants installed deer-proof fences. This attempt is expected to promote the conservation of rare plants and preserve the area's unique biodiversity.

In November 2023, we conduct observation of the growth status after installation. We found that the number of plants inside the fence had increased from about 10 types to about 30 types, and the golden orchid had increased from 4 to 8 plants. In addition, we have also confirmed the appearance of new species such as Viburnum erosum and Callicarpa japonica indicating that the recovery of species diversity is steadily progressing.

*1 Deer overpopulate, they eat plants that they do not eat before.

*2 Endangered class II(VU) of MOE, and C rank of Hyogo prefecture

Learn from the Forest" project in Hyogo

Golden orchid

Viburnum erosum

Actions in Mihara, Hiroshima to Preserve the Watershed of Hiroshima Plant

In 2008, we entered into a consignment contract with the Bisan District Forestry Association, which oversees the water source area of the Hiroshima Plant. As part of this partnership, they carry out forest conservation activities to protect and nurture a rich and healthy forest.

In October 2022, we collaborated with Mihara city in Hiroshima and the Bisan Forestry Association to organize the "Learn from the Forest" project. During the project, the participants, including Hiroshima plant employees, learned about the benefits of thinning trees in bringing sunlight into the forest, promoting the growth of many plant species, and improving water source cultivation functions while contributing to biodiversity conservation.

On the day of the project, the participants engaged in tree-thinning activities. Moreover, we selected and planted local native plants such as the Japanese maple and Prunus jamasakura, as they are well-suited for the local environment and provide a good combination for the area's biodiversity.

"Learn from the Forest" project in Hiroshima

Protecting Aso Grassland: The Water Source for our Kumamoto Plant

The Aso Grassland Restoration Committee is dedicated to preserving and replenishing the grassland areas surrounding the city of Aso in Kumamoto. To support their efforts, CCBJH has been donating funds, and since 2011 our employees have volunteered to assist with controlled thatch burning.

Burning dead grasses in the area has many benefits, including aiding in grassland restoration, water retention, landscape preservation, pest control, and protecting the ecosystem for endangered species. The Aso region is home to 56 endangered and rare species of plants and animals, including Jacob's ladder. By supporting grassland restoration, we are also helping to protect these diverse species.

Polemonium kiushianum

Shijimiaeoides divinus

In 2022, in conjunction with the United Nations Conference of the Parties to the Convention on Biological Diversity (COP15), we welcomed a lecturer from Aso Green Stock to hold a special internal lecture. The session focused on rare species in the Aso region, the importance of biodiversity, the function of carbon fixation, and the differences between the water resource cultivation functions of forests and grasslands. We are working to raise employee awareness of biodiversity conservation.

A special lecture about Aso grassland restoration

The 30 by 30 Alliance for Biodiversity

CCBJH has joined the 30 by 30 Alliance for Biodiversity a collaboration of 17 organizations drawn from private industry and public institutions including the Ministry of the Environment. Through this alliance we contribute to the maintenance of forests and conservation of biodiversity.

Water Source Forest Ebino Registered as OECM in Global Database

Coca-Cola Bottlers Japan Water Source Forest Ebino, which we have long protected as a water source area around Ebino Plant (Ebino city, Miyazaki Prefecture), has received certification from the Ministry of the Environment as a Nationally Certified Sustainably Managed Natural Site for the second half of FY2023. This recognition highlights our commitment to biodiversity conservation through private initiatives. It was registered in the global database as OECM* in August 2024.

Water Source Forest Ebino, covering about 203 hectares, is located in the water source area for our Ebino Plant. In 2014, we signed a four-party forest conservation agreement with Miyazaki Prefecture, the mountain-foot common forest, and the Nishimoro Forest Association, and have been engaged in water source replenishment activities. The 203-hectare woodland has been confirmed to be home to freshwater crabs, frogs and other amphibians, kites, blue pigeons, damselflies and other important species. Through the conservation of the forest in the water source replenishment area, we are contributing to the preservation of this rich diversity of life.

*Other Effective Area-Based Conservation Measures (OECM) refers to areas such as national parks that are not designated as protected but are still effective in conserving biodiversity over the long term.

I LOHAS Water source conservation project

A portion of the proceeds from sales of our "I LOHAS" brand mineral water is donated to support forest conservation activities in Japan. The forest plays an important role in preserving and protecting ground water. Protecting the forests means ensuring pure, clean and delicious water is available to future generations.

●Organizations to which we donate a part of sales through I LOHAS

| Production plant | Water source area | Organization |

|---|---|---|

| Zao Plant | Miyagi Prefecture | Shiraishi Zao Forest Association |

| Saitama Plant/Iwatsuki Plant | Gunma Prefecture | NPO Tonegawa Genryu Forest Development Corps |

| Ibaraki Plant | Ibaraki Prefecture | Tsukubane Forest Association |

| Tama Plant | Tokyo | Public Interest Incorporated Association of Tokyo Metropolitan Agriculture, Forestry and Fisheries Promotion Foundation, Creating Forests with Fewer Pollen |

| Ebina Plant | Kanagawa Prefecture | Atsugi City Forest Association |

| Hakushu Plant | Yamanashi Prefecture | Hokuto City |

| Tokai plant | Gifu Prefecture | Ena Nakanohou Suigen-no-mori Executive Committee |

| Production plant | Water source area | Organization |

|---|---|---|

| Kyoto Plant | Kyoto | Ujitawaracho Forest Association |

| Akashi Plant | Hyogo Prefecture | Hyogo Forestry Cooperative Federation |

| Oyama Plant | Tottori Prefecture | Tottori Hino Forest Association |

| Hiroshima Plant | Hiroshima Prefecture | Bisan District Forestry Association |

| Komatsu Plant | Ehime Prefecture | Ishizuchi Forest Association |

| Tosu Plant/Kiyama Plant | Saga Prefecture | East Saga Forest Association |

| Kumamoto Plant | Kumamoto Prefecture | Public Interest Incorporated Association of Aso Greenstock |

| Ebino Plant | Miyazaki Prefecture | Nishimoro Forest Association |

Five Initiatives for Water

Initiatives for water

At all the plants of Coca-Cola Bottlers Japan plants are committed to effective use and recycling of “water used for manufacturing.” We also continue to work to return “(an equal amount of) water used in our finished products” into nature through water resource conservation activities to improve the water source cultivation.

Water resource conservation

All plants identify the water resource areas of their plant and conduct scientific research to see if there are any problems with the amount and quality of water, and such. In addition, we make our efforts towards water resource conservation in cooperation with communities and experts in order to maintain the ability to continue to further foster and reserve water in the water resource areas.

Water intake and water quality management

In order to maintain water quality that meets the standards of the Coca-Cola system, all plants thoroughly check for any problems in the water they have pumped up, and work on managing it on a daily basis, considering water, which is the basis of safe manufacturing of products, as one of the raw materials.

We strictly control the amount of water used to manufacture our products so as not to waste water, which is one of the blessings of nature. Groundwater pumped from wells on the plant premises is monitored in accordance with the Coca-Cola system ‘s unique requirements for both the amount and quality, and is properly authorized and controlled under the laws of Japan. Based on a well-developed plan supported by local governments, all plants measure and monitor the amount of water intake 24 hours a day, and report it to local governments on a regular basis.

Efforts for efficient usage

Water is used in our products themselves, e.g. for extracting tea and coffee, as well as in the cleaning and disinfection processes of containers and lines. We thoroughly control the amount of water used in the production processes, and also recycle the water used.

As an example of measures to reduce the water consumption, we have introduced a chemical-free Electron Beam system. By sterilizing empty PET bottles without using any chemicals, approximately 400 tons of water has been reduced at new lines compared to the amount of water used per day by the previous system.

Furthermore, some of our plants reuse the water used for various processes including rinsing and heating by a process to remove contaminants with a special filter called RO* membrane for rinsing, heating, etc. again. In order to further improve water efficiency and reduce the amount of water every year, even just a little bit, we constantly review and improve the manufacturing processes and plant equipment.

*Reverse Osmosis: A water purification method that removes ions, molecules and other larger particles from water.

Wastewater management

We grasp the overview of watershed cycle plans formulated by local governments and conditions around the plants such as ordinances, water intake and drainage regulations, natural disaster hazards, etc. and continue our activities to maintain the quality of water intake and drainage that meet the standards of the Coca-Cola system. We have set voluntary standards for drainage treatment that are stricter than the legal standards, and strictly manage drainage treatment so as not to miss potential contaminated water. In addition, we have thoroughly complied with the Water Pollution Prevention Act, a water-related environmental laws and regulations.

Water used at plants for rinsing containers and equipment and cooling is discharged to sewers and rivers after proper treatment. Plants that discharge water to sewers remove suspended particles, adjust pH, etc., and release it after ensuring that the standards required by a local waterworks bureau as well as laws and regulations are complied with. Plants that discharge water to rivers purify it on their premises and comply with the water quality standards set forth in the domestic laws or the standards of the Coca-Cola systems, whichever is stricter. Treated water is once stored in a control tank on the plant premises and closely monitored to avoid water from flowing out of the plant premises before it is properly treated.

All plants carry out the secondary purification treatment for discharging water, cooling water, and sewage water with the activated sludge process using microorganisms.

Hiroshima Plant introduced a wastewater plant in 2020 and returns water after carrying out the tertiary treatment with special filters.

Primary treatment: Removal of any dirt caused by precipitation, etc. and large suspended particles

Secondary treatment: Decomposition of organic substances by microorganisms such as active sludge

Tertiary treatment: Treatment that precipitate impurities with special filters, flocculant, etc.

Water risk assessment

With the water risk assessment scheme of the Coca-Cola system, we utilize AQUEDUCT* of the World Resources Institute (WRI) and grasp areas of high water stress geographically. In addition, we identify risks of floods, landslide disasters, earthquakes, etc. based on the hazard map published by local governments.

As a framework for identifying water-related risks at each plant through scientific research, we conduct the Coca-Cola system's own Source Vulnerability Assessment (SVA) every five years at all plants and obtain approval from hydrology experts. In line with the SVA, we formulate a Water Management Plan (WMP), and implement initiatives for the conservation of water resources in a planned manner after obtaining approval from management. We evaluate the progress and effectiveness of the plan once a year.

Water-related risks are reported at the Risk Management Committee, together with the level of impact and the likelihood of occurrence of regulations by local governments, in the form of a summary of Enterprise Water Risk Assessment (EWRA). In addition, water risks and vulnerabilities specific to the place are summarized as a Facility Water Vulnerability Assessment (FAWVA) report that includes risk countermeasures based on detailed validation results, and the report is utilized for medium- to long-term strategies such as sustainable water resource conservation, reduced flood impact, and more efficient use of water by the Coca-Cola System in Japan.

*AQUEDUCT: A global tool for water risk assessment developed by WRI. It is used to assess water risks of the area in which the plant is located from the perspectives of the amount of water, its quality, regulations, and reputation.

External evaluations

Coca-Cola Bottlers Japan Holdings Inc. has achieved the highest A List rating in Water Security categories in the 2023 sustainability survey conducted by international non-profit organization CDP. This marks CCBJH made the A List for the first time for Water Security.

In April 2022, we signed The CEO Water Mandate, a global platform for water resource issues that supports corporate development, implementation, and disclosure of water sustainability policies and practices.

Initiatives for international standard for Waters Stewardship (AWS)

Through the implementation of AWS, the international standard for water stewardship and use of water resources, we aim to contribute to the sustainability of local water resources by promoting the AWS standard, a framework for the water stewardship and use of water resources.

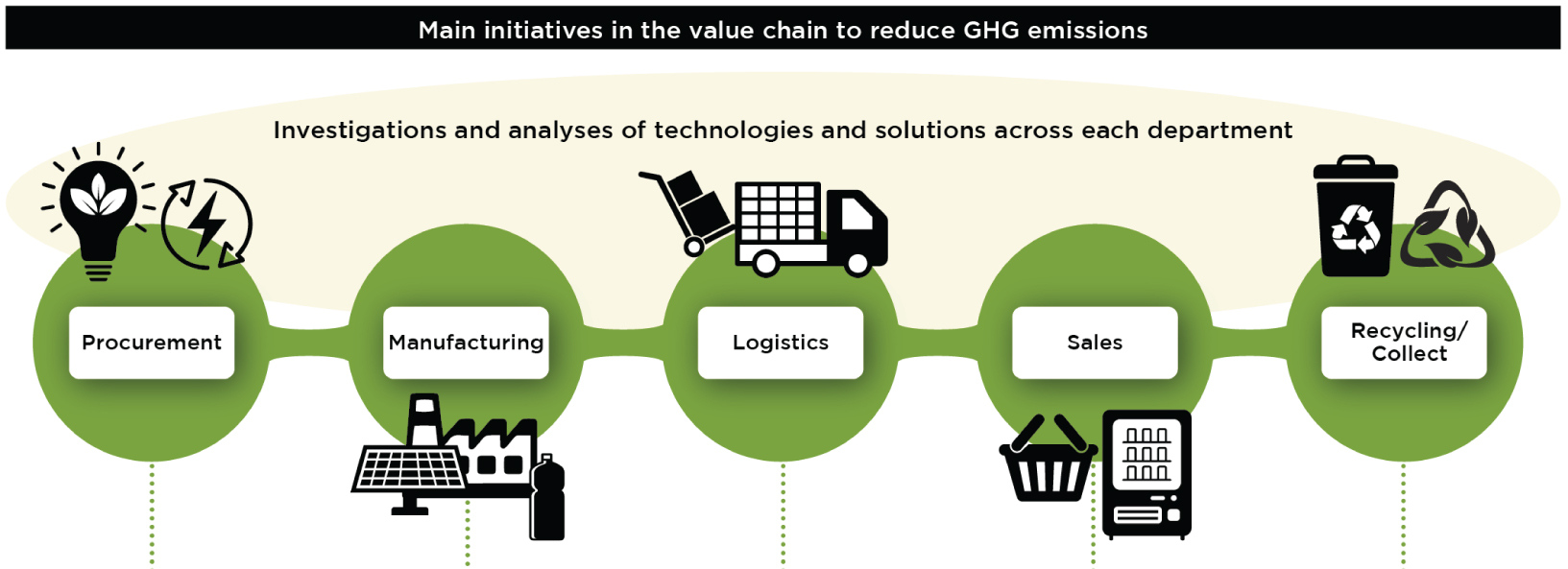

We believe that sustainable growth requires balancing the reduction of environmental impact with business growth. The CCBJH Group aim to contribute to the mitigation of climate change by reducing greenhouse gas emissions across our entire business, including in the procurement of materials, production, logistics/transportation, and sales, in order to "reduce greenhouse gas emissions by 50% (Scope1&2) by 2030","reduce greenhouse gas emissions by 30% (Scope3) by 2030", as stated in its own non-financial goals, the CSV Goals.

Related data (Coca-Cola Bottlers Japan Holdings Group)

We share information with our many stakeholders about the overall state of greenhouse gas emissions, the progress of countermeasures, and other topics so that this can lead to further emissions reductions.

Climate change initiatives

In October 2021, the new GHG emissions reduction target we formulated aims to quantify the total GHG emissions, both direct and indirect, from the activities of the Coca-Cola System in Japan based on the SBT Initiative*, and to reduce the absolute amount of Scope 1, 2 and 3 GHG emissions in each domain. The Coca-Cola System in Japan will continue to work to reduce Scope 1, 2, and 3 GHG emissions in all domains going forward and will actively contribute to the achievement of the Japanese government’s GHG reduction target (46% reduction in emissions compared to fiscal 2013 by fiscal 2030).

CCBJI completed an automated distribution center, “Akashi Mega DC,” with Japan’s largest storage and shipping capacities and started operation in July 2022. Warehouse operations such as sorting, picking and inventory storage previously carried out at each sales center will be gradually integrated into the Akashi Mega DC. Targeted sales centers, will become cross-docking type, with no inventory to build an efficient network that delivers products end-to-end to customers and vending machines.

The Shinsei logistics network optimization project is driving the strategic transformation of our logistics as a whole by introducing new distribution centers—primarily mega distribution centers and others such as the Hakushu and Kumamoto warehouses—and reorganizing as well as consolidating hub warehouses and sales centers to streamline complex supply chains. Through these efforts, the CCBJH Group is optimizing its supply chain to resolve a variety of issues, such as reducing their environmental impact.

*The calculation of greenhouse gas emissions at the company level is consistent with the greenhouse gas protocol standard (company emissions and company value chain; Scope 3 standard), a best practice standard for company greenhouse gas emissions administered by the World Business Council for Sustainable Development (WBCSD) and the World Resources Institute (WRI).

Procurement

-

Introducing sustainable materials

-

Identifying and employing renewable energy sources

-

Purchasing green electricity certificates

Manufacturing

-

Improving energy efficiency across all plants

-

Developing energy efficient manufacturing lines

-

Installing solar panels at plants

-

Manufacturing labelless products

Logistics

-

Mega DCs to optimize supply chains

-

Streamline transport volumes and fuel consumption through small-capacity preform loading*¹

-

Implementing modal shifts

-

Efficient sales and delivery routes reduces number of vehicles used and fuel consumption

Sales

-

Deploying peak shift vending machines reduces energy requirements by up to 95%

-

Introducing sales equipment that effectively reduce power requirements and greenhouse gases

Recycling/Collect

-

Partnerships with business and local governments to create a new PET bottle resource circulation system

-

100% recycled coffee grinds and used tea leaves

-

Promote resource recycling through education campaigns to encourage sorting used product containers

-

Promoting horizontal recycling initiatives, including “CAN to CAN” and “pallet-to-pallet”

*¹ Preform is the prototype of a PET bottle like a test tube

*² Peak shift vending machines are vending machines that reduce power consumption during the day by centrally cooling at night.

Production initiatives

At our plants, we are actively adopting new processes and the latest technology for improving energy efficiency. We are striving to reduce the greenhouse gases produced and fuel oil used in our manufacturing processes through measures such as introducing cogeneration systems that can create both electric power and heat from a single energy source, installing insulation and heat exchange systems that can effectively keep energy losses to a minimum, and converting from the use of fuel oil to natural gas.

(Energy Use Ratio)

per liter of product

year on year)

Initiatives in Logistics Transport divisions

For site-to-site transport between plants or warehouses, we are accelerating efforts to improve the load rate using larger vehicles and continue to utilize modal shift for further transport efficiencies. We are also streamlining delivery routes to customers, pushing eco-driving, promoting the replacement of fuel-efficient vehicles such as hydrogen trucks, electric vehicles and hybrid vehicles, and using smaller sales vehicles to reduce greenhouse gas emissions in the entire Group.

Efforts to reduce CO2 emissions

The model for PET bottles is called a “preform”, and they can be transported in large volumes due to their small size.

This enables a reduction in fuel usage and significant decreases in nitrogen oxide and carbon dioxide emissions.

Sales initiatives

To reduce the energy consumption and CO2 emissions of our vending machines (including coolers and drink dispensers), we continuously work toward the development and introduction of new equipment.

Our "peak shift" vending machines, which we have been deploying since 2013, shift electricity consumption used for cooling to nighttime, which can reduce power consumption during peak daytime hours by a maximum of 95%. The energy-saving specifications of these machines allow them to provide cold products 24 hours a day, even if the power for cooling is completely stopped for as long as 16 hours. We are also progressing with our plan to eliminate the use of chlorofluorocarbon (CFC) refrigerants in our vending machines.

machine ratio

vending machines,

including peak shift

vending machines

December 2023)

Other initiatives

●Endorsement of the Leading Tenant Action Plan

We have endorsed the Leading Tenant Action Plan, a list of decarbonization initiatives by tenant companies compiled by the Ministry of the Environment.

The Leading Tenant Action Plan is designed to promote the reduction of CO2 emissions from office buildings, which account for a high percentage of greenhouse gas emissions (GHG) in Japan, and compiles initiatives that building tenants have started to achieve decarbonization, such as shifting to ZEB*.

In the future, we will promote initiatives to decarbonize our workplace, such as by conserving energy and utilizing renewable energy, in cooperation with building owners and in line with this Action Plan.

*ZEB is an abbreviation of “Net Zero Energy Building”.

This refers to buildings that aim to reduce the annual revenue and expenses related to their primary energy consumption to zero, while also providing a comfortable indoor environment.

●Endorsement of the TCFD recommendations

In February 2022, we endorsed the recommendations by the Task Force on Climate-related Financial Disclosures (TCFD) and participated in the TCFD Consortium, a forum for discussion among the supporting firms and financial institutions. Based on these recommendations, we will analyze the financial impact of climate change-related risks and opportunities, consider measures to address them, and strive for enhanced information disclosure from the perspectives of the core elements of governance, strategy,

●Endorsement of the GX League Basic Concept

The Ministry of Economy, Trade and Industry established the GX League as a forum for companies, government, and academia working on Green Transformation (GX), which is a transformation of the entire economic and social system toward achieving carbon neutrality by 2050, to collaborate in discussions toward GX and implement new market building. We stand in agreement with the GX League Basic Concept, the basic guideline for promoting GX, and will continue to work toward achieving a decarbonized society.

●Participation in and support of the Japan Climate Initiative

In March 2022, we endorsed and participated in the declaration of Japan Climate Initiative (JCI), a network of companies and local governments in Japan promoting climate change action. We will continue to strive to achieve the GHG emissions reduction targets set by the Coca-Cola System in Japan by 2030.

Hakushu Plant's "Furusato Hydropower Plan" renewable energy

Since 2019 and the conclusion of a contract for the Furusato Hydropower Plan offered by Yamanashi Power Plus—a power supply brand jointly operated by Yamanashi Prefecture and TEPCO Energy Partner, Incorporated—our Hakushu Plant has been utilizing hydroelectric power.

Yamanashi Power Plus "Furusato Hydropower Plan" is an initiative to enhance the environmental value through the realization of zero CO2 emission achieved by limiting the source of power supply to only the hydroelectric power generated in the hydraulic power plant run by Yamanashi Prefecture Enterprise Bureau. The reason why this plan can eliminate the CO2 emission that is normally associated with the use of electricity is because hydroelectric power is a renewable type of energy that does not emit any CO2 when it is generated. As a company that is working proactively to reduce the environment burden, CCBJI agreed to cooperate and became a certified enterprise in support of this initiative. With the conclusion of the power supply contract, CCBJI pays an extra 1 yen per kilowatt-hour as environmental added value in addition to the regular electricity charge. Part of the proceeds from this extra payment will be used to fund environment conservation projects of Yamanashi Prefecture.

Through this initiative, we are working to reduce environmental impact by eliminating CO2 emissions associated with electricity use.

(Left) Takano, Director General Enterprise Bureau, Yamanashi Prefecture

(Right) Takayuki Hirayama, Plant Manager Hakushu Plant,Coca-Cola Bottlers Japan, Inc.

Ibaraki Plant "Aqua Premium"

"Aqua Premium" is a plan to purchase electricity only for hydroelectric power generation that does not emit CO2 during power generation provided by TEPCO Energy Partner. We pay the electricity charge (environmental added value) in addition to the regular electricity charge and use it as power for Ibaraki Plant.

Tama Plant "Tradable Green Certificate"

The "Tradable Green Certificate" is a system certifying that it is electricity generated from natural energy by a third-party certification organization. We pay the electricity charge (environmental added value) in addition to the regular electricity charge and use it as power for Tama Plant.

Install sola power generation and use it as its own electricity

Solar panels were installed at the plant tour facilities of the Tokai, Hiroshima and Ebino plants to supply electricity. Transparent solar panels were installed at the Hiroshima plant completed in October 2020.