What we are doing

- In order to make effective use of valuable resources in a sustainable manner, we will make continuous devise and improve ways to contribute to environmental protection.

- CSV Goals (Creating Shared Value)

-

*The base year is 2015 and the target year is 2025 unless otherwise noted.

Packaging & Recycling

(Circular Economy)Design

- 100% : Content of sustainable materials* by 2030

- 100% : Use sustainable materials in PET bottles of all products (based on unit sales)

- 35% : Further lightweight PET packaging (compared to 2004) by 2030

Collect with partner

- 100% : Collection percentage compared to sales volume by 2030

- Extensive partnerships across industry and environmental organizations by 2030

*Sustainable materials:Total of recycle PET material and bio-based PET plastic.

- Policy

- Policy on environment

Packaging & Recycling(Circular Economy)

Recycling Materials & Packages

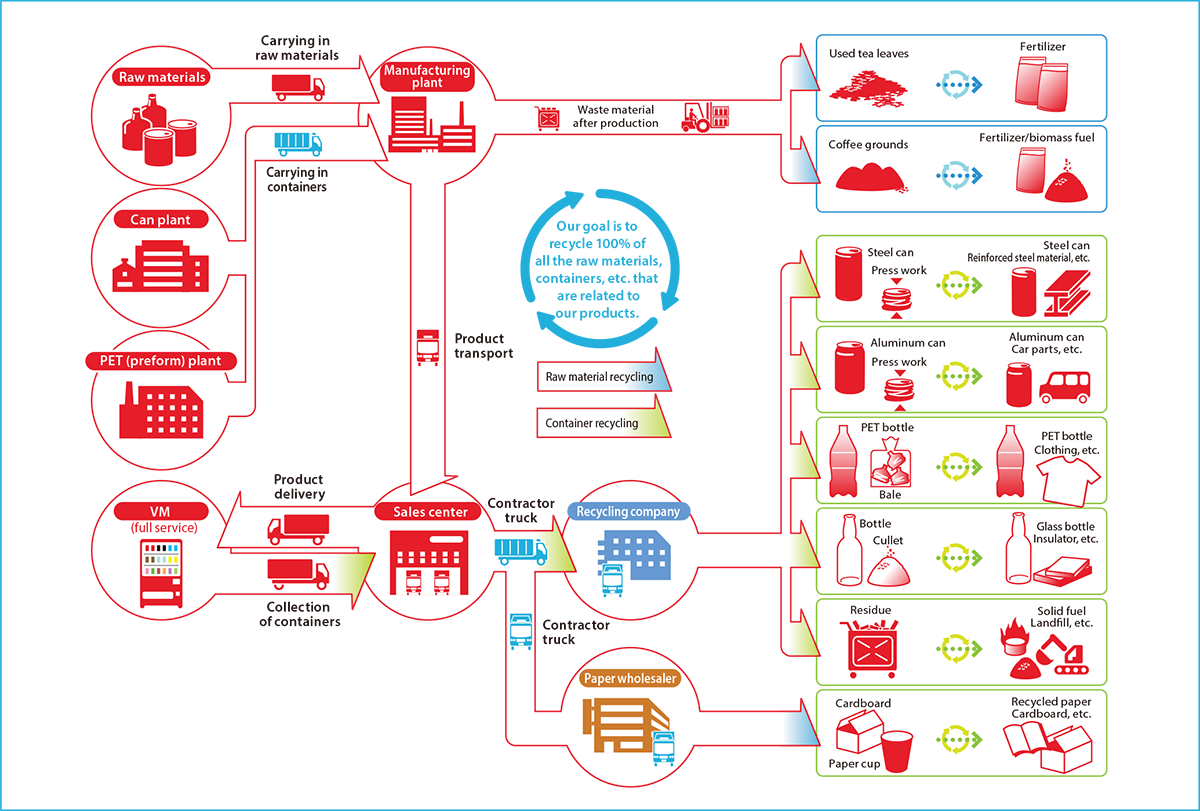

We work to minimize our environmental impact by collecting and recycling waste generated at each stage of the product life cycle wherever possible. Our initiatives include reducing waste from production, minimizing product disposal loss through inventory control, horizontal recycling of empty containers, and adopting environmentally friendly packaging materials.

Recycling of Plant Waste

Recycling waste materials at our plants, we sort and recycle waste materials generated by production to continuously aim to achieve zero waste emissions. Coffee grounds and tea leaves constitute the bulk of our generated waste materials, and we have achieved 100% and 100% recycle rates for them, respectively, as fertilizer or animal feed.

For example, the used tea leaves that result from the production of Sokenbicha at the Zao Plant are combined with byproducts, such as leftover whey from the manufacturing of cheese at the Zao Dairy Center, and used as "eco-feed" * for Zao Sosei beef cattle. Working with the local government and members of academia, the Tokai Plant is also pursuing research into a way to efficiently reuse coffee grounds and tea leaves.

* Food scraps that become feedstuff for animals. The Japanese Ministry of Agriculture, Forestry and Fisheries is actively promoting eco-feed to increase the self-sufficiency rate for feedstuff.

of waste

from plants Approx

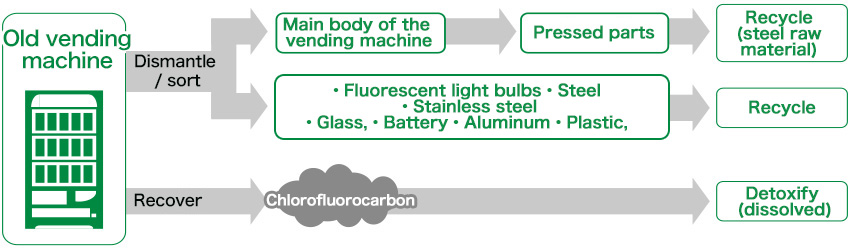

Recycling Vending Machines

We recycle vending machines that are taken out of service for disposal. Such vending machines are collected at our company's facilities, dismantled and sorted according to waste material type, and the chlorofluorocarbon is appropriately disposed.

Basic principle on environment

We consider handing over global environment in sustainable form to next generations is our vital mission by effectively leveraging natural resources including water indispensable for our businesses. To this end, we drive global environmental stewardship through innovations that achieve both mitigation of environmental burden and business growth.

We also materialize CSV (Creating Shared Value) with local communities through preservation of natural environment and environmental awareness-raising therein.

Policy on environment

We operate our business along with the following environmental policy.

- Mitigation of environmental burden

We seek to mitigate environmental burden in our product life cycle, namely throughout the processes of procurement of materials, production, logistics, storage, sales, recovery and recycling. We also consider environmental burden in developing new products, implementing services, selecting suppliers and so on.

- Water resource conservation

We strive to reduce water to be used for manufacturing and treat it properly. Moreover, we work on conserving water resources through collaborations with local communities in order to hand over rich water resources to next generations.

- Mitigation of climate change

In addition to making contributions to mitigate climate change, we engage in initiatives to reduce greenhouse gas emissions at all business areas for sustainable growth of our businesses.

- Efficient use of resources

We invest appropriate corporate resources to establish sustainable society with circular economy and to efficiently use the resources such as water and energies.

- Food loss & waste reduction

We train employees to prevent food waste and optimize production and work closely with supply chain partners to reduce the total volume of food loss & waste.

We provide product storage instructions and freshness rules to customers and collaborate with industry associations and peers how to show bestbefore-dates to consumers.

We provide variety of serving sizes for our products to fit the needs of consumers.

We collaborate with customers, business partners, industry associations, regulators, academia, NPOs and our communities to support programs aimed at using food loss & for alternative uses. We also engage with them to identify and implement innovate solutions that help prevent food loss to reduce the amount of food loss & waste in our value chain. - Conservation of Natural Habitats, Biodiversity and Ecosystems

We identify and help protect natural habitats from conversion.

Natural ecosystems are not altered or burned for conversion to new production. We promote and protect natural habitats, protected areas and biodiversity, through the protection, and where possible, restoration of ecosystem services through approaches that build resilience to longer-term climate stressors. - Communications

We focus on communications with stakeholders including local communities and act as a trusted company exceeding their expectations, aiming for meeting each of their needs.

- Environmental awareness-raising

We offer various opportunities and activities of enlightenment to raise awareness on environment for those in local communities and all who are involved in our business. We also play an active role in community activities on environment.

- Improvement of environmental performances

We work on continuous improvement of environmental performances by regularly reviewing our environmental targets proactively and as needed.

- Compliance of laws and regulations

We set up more stringent voluntary standards according to the request of The Coca-Cola Company, not to mention our compliance to environment-related laws and regulations, ordinances and various agreements.

- Supplementary provision

The policy is enacted and enforced effective January 1, 2018.

(Revised in June 2021)