News Release

Coca-Cola Bottlers Japan starts joint project with Far Eastern New Century in Taiwan on commercialization of PET bottles made from recycled PET raw material through chemical recycling

News Release

July 29, 2020

Coca-Cola Bottlers Japan Inc.

Coca-Cola Bottlers Japan starts joint project with Far Eastern New Century in Taiwan on commercialization of PET bottles made from recycled PET raw material through chemical recycling

Coca-Cola Bottlers Japan Inc. (Headquarters in Minato-ku, Tokyo; Representative Director & President Calin Dragan; hereafter “CCBJI”) started a joint project with Far Eastern New Century Corporation (Headquarters in Taipei, Taiwan, R.O.C.; Chairman Douglas Tong Hsu; hereafter “FENC”), one of the world's largest manufacturers of PET resin and polyester fibers, based in Taiwan, to commercialize PET bottles using recycled PET raw materials through chemical recycling (Note 1). This project aims to carry out pilot sales of PET-bottled product using recycled PET raw materials in some of our sales areas by the end of the year and expand opportunities to leverage this PET raw material at commercial scale in several years.

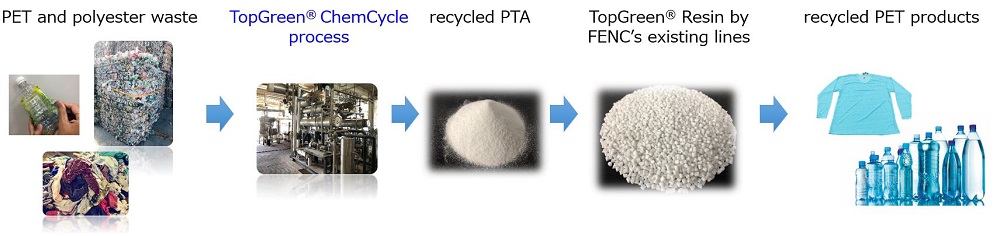

A part of the raw materials for recycled PET resin used in this project is manufactured using a new approach to chemical recycling, TopGreen® ChemCycle, developed by FENC, a first in the world. TopGreen® ChemCycle chemically converts used PET bottles into one of the main components of PET resin, rPTA (recycled Purified Terephthalic Acid), and using rPTA as a raw material, manufactures ChemCycle resin with the quality equivalent to that of virgin PET resin (new PET resin made from fossil fuels). Also in scope upon full commercialization of the TopGreen® ChemCycle process will be using both used PET bottles and polyester labels, etc as raw materials for the manufacture of rPTA.

【Manufacturing Process of Recycled PET Products by Chemical Recycling】

In general, chemical recycling processes other than TopGreen® ChemCycle convert used PET bottles back into an intermediate raw material produced during manufacturing of PET resin, and after refining it, repolymerize it into PET. On the other hand, TopGreen® ChemCycle, which was newly-developed by FENC, converts used PET bottles further into PTA, a raw material of PET resin. By converting further into PTA, it has achieved manufacturing of PET resin with the quality closer to that of virgin PET resin. The project will use rPTA manufactured through TopGreen® ChemCycle as part of the raw materials to produce PET resin, and achieves levels of quality and safety equivalent to those of conventional PET bottle raw materials.

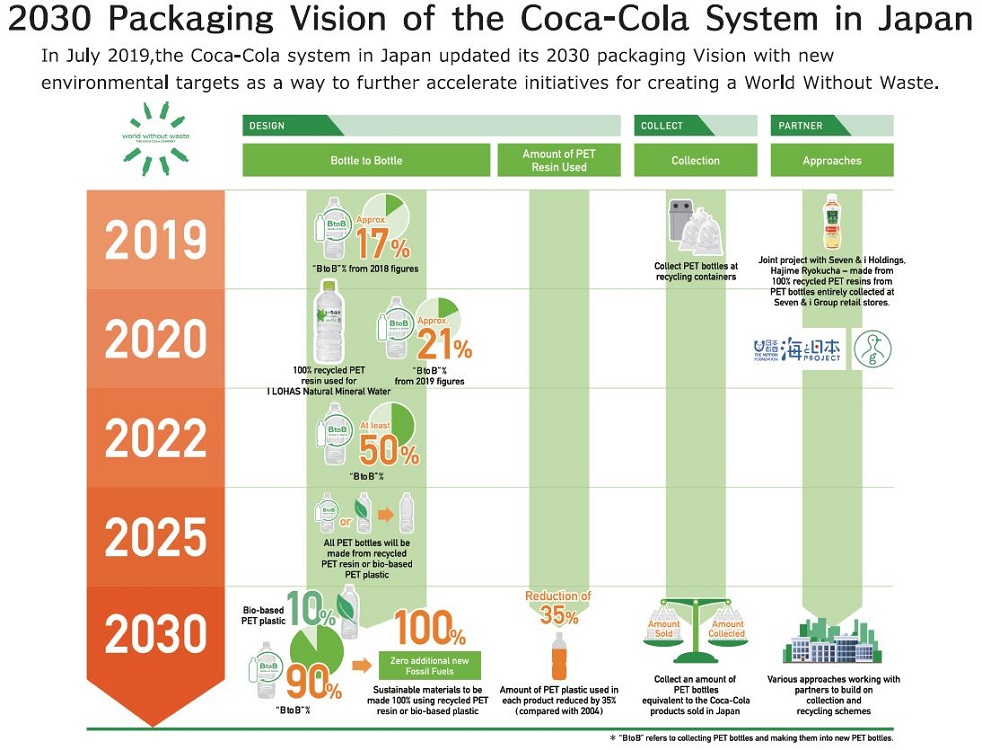

For over 30 years, FENC has been addressing PET resin recycling, particularly focusing on chemical recycling. CCBJI’s ambition is to use sustainable PET resin materials in all PET products by 2025, as declared in the Coca-Cola System’s "2030 Packaging Vision", and we have been working on the expansion of bottle-to-bottle recycling and sourcing nonpetroleum-derived raw materials for PET bottles. For this reason, CCBJI supports establishing a scalable chemical-recycling process for PET resin, and we initiated this joint project together with FENC, to pilot the innovative TopGreen® ChemCycle process.

Note 1: What is chemical recycling?

After collected used PET bottles have been sorted, crushed, and washed to remove foreign materials, they are broken down into a raw material or an intermediate raw material of PET resin by depolymerization, and then the raw material is refined and polymerized into new PET resin. To depolymerize raw materials, ethylene glycol (EG) is added to convert them back to BIS-2-hydroxyethylterephthalate (BHET), the intermediate raw material produced during resin manufacturing. After refining, it is repolymerized into PET. Chemical recycling is characterized by the removal of foreign and heterogeneous materials during depolymerization/repolymerization, enabling regeneration of PET resin with the same high quality as that of virgin resin.

(Source: The Council for PET Bottling Recycling)

■What is the "2030 Packaging Vision" (https://en.ccbji.co.jp/csv/environment/?id=tab3)

【About Far Eastern New Century Corporation】

Founded in 1949 with its headquarters in Taipei, Taiwan, Far Eastern New Century Corporation is one of the leading chemical manufacturers in the world. The company has 247 group companies, nine of which are listed on the Taiwan Stock Exchange, with 65,500 employees and 24.3 billion dollars in revenue in 2019. The company is ranked 2nd for the recycled resin business globally. In Japan, the company founded Far Eastern Ishizuka Green PET Corporation (FIGP) in May 2012 jointly with Ishizuka Glass Co., Ltd., a total package manufacturer in Japan. Its headquarters and Tokyo Plant are located in Sakai-cho, Sarushima-gun, Ibaraki Prefecture. FIGP runs a “bottle-to-bottle” mechanical recycling business and produces/sells recycled PET (R-PET) resin for beverage and non-beverage manufacturers. FIGP Tokyo Plant started commercial production in 2014 and became the largest R-PET plant in Japan with annual bale throughput of 50,000 tons and R-PET resin production of 35,000 tons.

Please see here for the PDF version.

※Please note that the information contained in news releases is current as of the date of release. Certain information may have changed since the date of release.